| Six-Axis Robot | Tuling | Core Components | Laser Source |

| Usage | Weld Metal | Max. Output Power | 2000W |

| Applicable Material | Metal | Cnc Or Not | Yes |

| Cooling Mode | Water Cooling | Electrical And Pneumatic Systems | Schneider |

| Wavelength | 1090Nm | Laser Power | 1000w/ 1500w/ 2000w |

| Weight (Kg) | 600 Kg | Certification | Ce, Iso9001 |

| Core Components | Fiber Laser Source, Fiber, Handle Laser Welding Head | Key Selling Points | High-Accuracy |

| Function | Metal Part Laser Welding | Fiber Length | ≥10m |

| Applicable Industries | Hotels, Garment Shops, Building Material Shops | Core Components | Laser Source |

| Mode Of Operation | Pulsed | After Warranty Service | Online Support |

| Focal Spot Diameter | 50μm | Maximum Coverage | 1730mm |

| Video Outgoing Inspection | Provided | Graphic Format Supported | Ai, Plt, Dxf, Dwg, Dxp |

| Place Of Origin | Jinan,Shandong Province | Warranty Time | 3 Years |

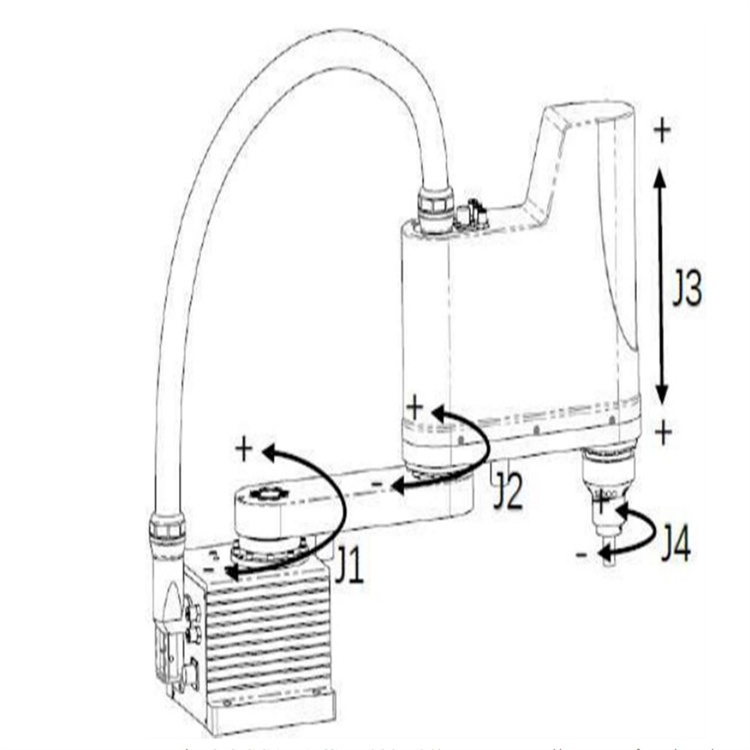

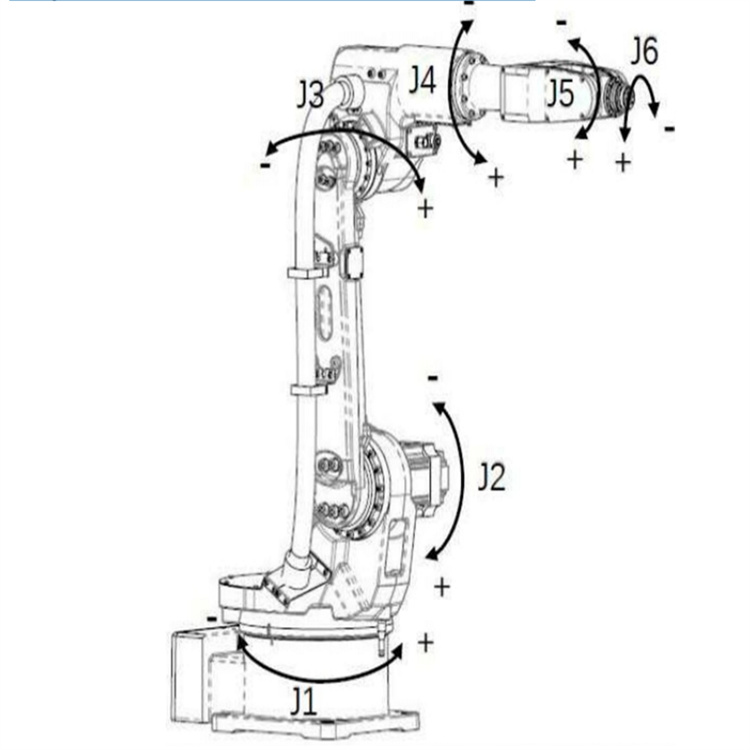

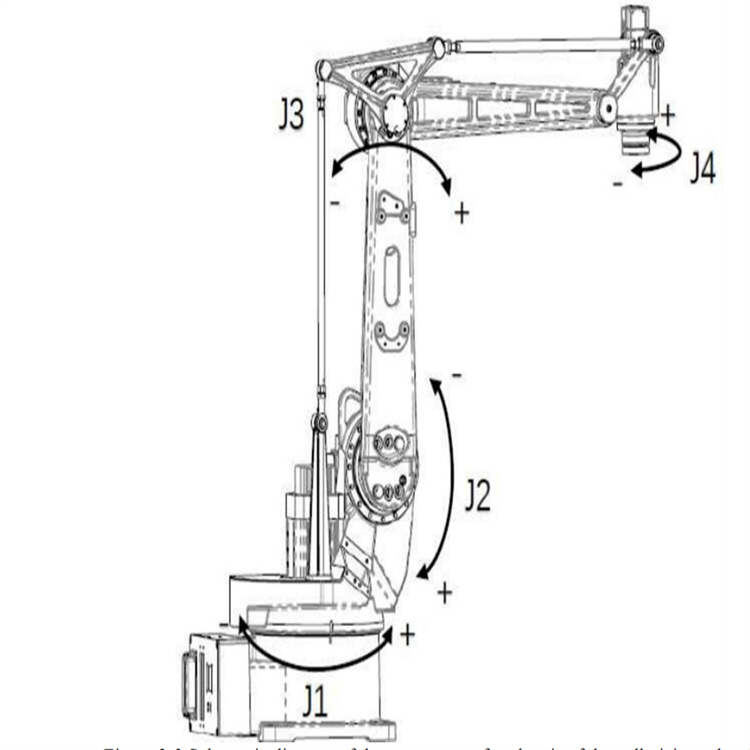

1.Machinery Manufacturing Field With the intensification of welding tasks in the machinery manufacturing industry, the welding operation has inherently poor working conditions and large heat radiation, which is a highly dangerous occupation. There are also many large-scale equipment in machinery manufacturing, which also increases the difficulty of welding. , Welding robot is an automatic mechanical equipment engaged in welding work, which liberates the labor intensity of workers and helps improve the level of automation in the field of machinery manufacturing. 2.Automobile and auto parts : In recent years, in order to meet the needs of the public, the automobile industry has shown diversified development. Traditional welding cannot meet the high welding requirements of automobile and auto parts manufacturing. , The welding seam is beautiful and firm. In many modern automobile production workshops, welding robot assembly lines have been formed. 3.Electronic equipment: The field of electronic equipment has relatively high requirements for welding quality. With the increasing demand for electronic equipment in the society, electronic equipment is also facing severe challenges while developing rapidly. Welding robots can stabilize welding quality while ensuring production efficiency. The precise welding of the equipment is three to four times higher than that of manual labor. 4. Aerospace: In the structure of the aircraft, there are nearly 1,000 welding components of the body, and nearly 10,000 parts are involved. Most of the important load-bearing components of the aircraft use welded components. The aircraft body is under great pressure during flight, so welding The requirements are relatively strict, and the welding robot can flexibly set the welding parameters through the automatic welding seam tracking technology to accurately weld the aircraft structure. The robot axis can be a rotary axis or a translation axis, and the operation mode of the axis is determined by the mechanical structure. The robot axis is divided into the motion axis of the robot body and the external axis. The external shaft is divided into sliding table and positioner. Unless otherwise specified, the robot axis refers to the motion axis of the robot body. Turing robots are divided into three types of industrial robots: Industrial six-axis robot: including six rotation axes SCARA: contains three rotation axes and one translation axis Palletizing manipulator: including four rotating shafts The joint motion of the robot is shown in the figure.

1.Machinery Manufacturing Field With the intensification of welding tasks in the machinery manufacturing industry, the welding operation has inherently poor working conditions and large heat radiation, which is a highly dangerous occupation. There are also many large-scale equipment in machinery manufacturing, which also increases the difficulty of welding. , Welding robot is an automatic mechanical equipment engaged in welding work, which liberates the labor intensity of workers and helps improve the level of automation in the field of machinery manufacturing. 2.Automobile and auto parts : In recent years, in order to meet the needs of the public, the automobile industry has shown diversified development. Traditional welding cannot meet the high welding requirements of automobile and auto parts manufacturing. , The welding seam is beautiful and firm. In many modern automobile production workshops, welding robot assembly lines have been formed. 3.Electronic equipment: The field of electronic equipment has relatively high requirements for welding quality. With the increasing demand for electronic equipment in the society, electronic equipment is also facing severe challenges while developing rapidly. Welding robots can stabilize welding quality while ensuring production efficiency. The precise welding of the equipment is three to four times higher than that of manual labor. 4. Aerospace: In the structure of the aircraft, there are nearly 1,000 welding components of the body, and nearly 10,000 parts are involved. Most of the important load-bearing components of the aircraft use welded components. The aircraft body is under great pressure during flight, so welding The requirements are relatively strict, and the welding robot can flexibly set the welding parameters through the automatic welding seam tracking technology to accurately weld the aircraft structure. The robot axis can be a rotary axis or a translation axis, and the operation mode of the axis is determined by the mechanical structure. The robot axis is divided into the motion axis of the robot body and the external axis. The external shaft is divided into sliding table and positioner. Unless otherwise specified, the robot axis refers to the motion axis of the robot body. Turing robots are divided into three types of industrial robots: Industrial six-axis robot: including six rotation axes SCARA: contains three rotation axes and one translation axis Palletizing manipulator: including four rotating shafts The joint motion of the robot is shown in the figure.

- Wire feeding mechanism. Including whether the wire feeding distance is normal, whether the wire feeding conduit is damaged, and whether there is an abnormal alarm; Whether the gas flow is normal; Whether the welding torch safety protection system is normal. (It is forbidden to close the welding torch for safety protection work) ;Whether the water circulation system is working normally;Test TCP (it is recommended to compile a test program and run it after each shift)